Diamond Wheel Troubleshooting Guide

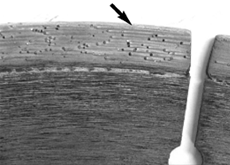

Wheel will not cut (Glazing)

Note: A "glazed" wheel can be refreshed by slowly cutting into a soft concrete block.

Reason: Diamond bond is too hard for material being cut. A hard diamond bond will not allow required bond wear to expose new diamond surfaces.

Solution: Change to wheel with a softer diamond bond. It is important to use the correct wheel for the material as indicated in the application guide.

Reason: Diamond bond is too hard for material being cut. A hard diamond bond will not allow required bond wear to expose new diamond surfaces.

Solution: Change to wheel with a softer diamond bond. It is important to use the correct wheel for the material as indicated in the application guide.

Reason: Diamond bond is too hard for material being cut. A hard diamond bond will not allow required bond wear to expose new diamond surfaces.

Solution: Change to wheel with a softer diamond bond. It is important to use the correct wheel for the material as indicated in the application guide.

Reason: Insufficient machine power or RPM applied. STIHL diamond wheels have been designed to run on STIHL Cutquik® cut-off machines.

Solution: Ensure adequate machine power and operation. Check and tighten drive belt to provide appropriate torque transfer.

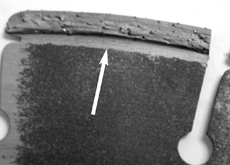

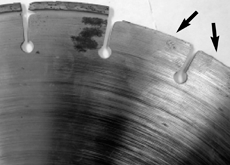

Overheating (Dark areas under segments)

WARNING! Overheating a diamond wheel may cause structural damage, causing it to break apart or release segments during use that could result in serious or fatal injury. A diamond wheel must be replaced immediately if it shows signs of exposure to excessive heat. Never start or operate any machine with a damaged diamond wheel.

Reason: Insufficient cooling at the cutting surface. The life of a diamond wheel is significantly reduced when exposed to extreme heat.

Solution: Frequently remove wheel from cut to cool. After every 30 seconds of dry cutting, allow running wheel to cool in air for 10 seconds.

Loss of Tension (Wheel is not flat)

WARNING! A distorted diamond wheel may break apart or release segments during use that could result in serious or fatal injury. Do not attempt to straighten or repair a distorted wheel. A diamond wheel must be replaced immediately if it shows signs of core tension loss. Never start or operate any machine with a damaged diamond wheel.

Reason: Wheel has overheated due to a lack of cooling. Excessive heat will cause the steel core to warp and discolor.

Solution: Frequently remove wheel from the cut to cool. After every 30 seconds of dry cutting, allow running wheel to cool in air for 10 seconds.

Reason: Improper wheel selection. An improper wheel will flex excessively, creating permanent stress in the steel core.

Solution: Consult wheel application guide for correct wheel.

Reason: Cutting material has worn against side of wheel. Do not turn or twist the machine while wheel is cutting.

Solution: Use wheel to cut only in straight lines. Insure material is not able to collapse or pinch the wheel when engaged in cut.

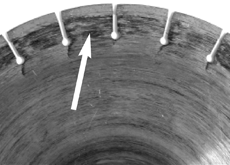

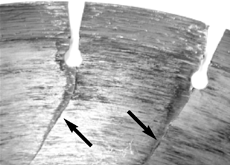

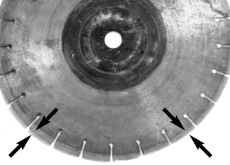

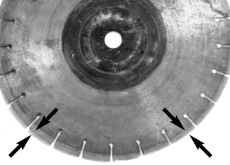

Undercutting

WARNING! A severely undercut diamond wheel may break apart or release segments during use that could result in serious or fatal injury. A diamond wheel must be replaced immediately if the core has been severely undercut. Never start or operate any machine with a damaged diamond wheel.

Reason: Cutting very abrasive material. This is a normal condition when cutting asphalt or green concrete.

Solution: If available, use water spray to flush the kerf. Several STIHL wheels are available with undercut protection segments.

Reason: Cutting into the sub-base. Cutting into sand or dirt will cause severe undercutting.

Solution: Do not cut completely through the material.

Reason: Cutting material has worn against side of wheel.Do not turn or twist the machine while wheel is cutting.

Solution: By only cutting the intended material, the wheel life will be extended.

Diamond Segment Loss

WARNING! A diamond wheel with segment loss may increase reactive forces or continue to break apart or release segments during use that could result in serious or fatal injury. A diamond wheel must be replaced immediately if there is a segment loose, cracked or missing. Never start or operate any machine with a damaged diamond wheel.

Reason: Wheel has been twisted or jammed. Only use a diamond wheel to make straight cuts in recommended materials.

Solution: Hold machine straight while cutting. Secure material being cut to prevent accidental pinching or binding.

Reason: Wheel has overheated due to a lack of cooling. Excessive heat will cause the steel core to fracture.

Solution: Frequently remove wheel from the cut to cool. After every 30 seconds of dry cutting, allow running wheel to cool in air for 10 seconds.

Reason: Severe undercutting has occurred.

Solution: If available, use water spray to flush the kerf. Many STIHL wheels are available with undercut protection segments.

Reason: Improper wheel use causing excessive dullness. A dull wheel can have segments separate due to impact, fatigue or frictional heat.

Solution: Use proper wheel type for material being cut.

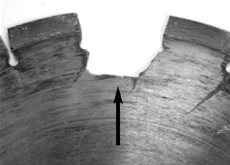

Cracks in Metal Core

WARNING! A cracked diamond wheel may break apart or release segments during use that could result in serious or fatal injury. A diamond wheel must be replaced immediately if the core or segment show signs of cracking. Never start or operate any machine with a damaged diamond wheel.

Reason: Extreme pressure was applied during cutting.

Solution: Apply light pressure while cutting.

Reason: Wheel has overheated due to a lack of cooling. Excessive heat will cause the steel core to fracture.

Solution: Frequently remove wheel from the cut to cool. After every 30 seconds of dry cutting, allow running wheel to cool in air for 10 seconds.

Reason: Improper wheel selection. An improper wheel will cause excessive stress in the steel core causing it to crack.

Solution: Consult wheel application guide for correct wheel.

Out of Round (Eccentric Wear)

WARNING! A severely out of round diamond wheel can cause excessive vibration and damage to the machine or work piece. Such vibration or damage could result in personal injury. A diamond wheel must be replaced immediately if it is severely out of round. Never start or operate any machine with a severely out of round diamond wheel.

Reason: Arbor shaft bearings worn. Worn bearings allow arbor shaft to run eccentrically, causing the wheel to wear out of round.

Solution: Install new shaft bearings. Arbor bearings and shaft should be inspected frequently and checked for signs of wear.

Reason: Wrong wheel selection for application. Improper selection of wheel bond causes the wheel to “pound” and not cut.

Solution: Use proper wheel type for material being cut. Consult the recommended application guide to determine correct wheel.

Reason: Worn arbor shaft. Improperly tightened wheel flanges will allow wheel to spin and groove arbor shaft.

Solution: Replace arbor shaft. Always correctly tighten wheel flanges to prevent damage to wheel and arbor.

Reason: Wheel arbor hole is out of round or damaged. Ensure that the arbor shaft size exactly matches the size of the wheel arbor hole.

Solution: Replace wheel. Never operate any machine with a damaged wheel.

Damaged or Distorted Arbor Hole

WARNING! A diamond wheel with a damaged or distorted arbor hole can cause excessive vibration and damage the machine or work piece. Such vibration or damage could result in personal injury. A diamond wheel must be replaced immediately if it has a damaged or distorted arbor hole. Never start or operate any machine with a damaged or distorted arbor hole.

Reason: Wheel not properly mounted on arbor shaft. If this occurs, the operator will experience a pounding effect or side-to-side cutting stress.

Solution: Mount wheel properly onto arbor shaft. Mount wheel securely on shaft and tighten mounting bolt to the proper torque.

Reason: Worn or loose mounting flanges. Worn or loose flanges can cause the wheel to “flutter,” resulting in arbor hole distortion.

Solution: Inspect flanges and replace if needed. Both the inner and outer flanges should be replaced if required.

Reason: Arbor shaft worn or grooved. The wheel will pound in the cut if excessive arbor wear has occurred.

Solution: Replace arbor shaft if signs of wear or damage.

Reason: Arbor hole size is larger than the arbor shaft.

Solution: Replace wheel with correct size wheel.